Essential Tips for Maintaining and Extending the Life of Your Rotary Tools

Introduction

Rotary tools are versatile and essential tools for many DIY enthusiasts and professionals. They can be used for a wide range of projects, from carving and engraving to sanding and grinding. However, like any other tool, rotary tools require proper maintenance to ensure they function optimally and last longer.

In this article, we will provide you with essential tips on maintaining and extending the life of your rotary tools. We will cover everything from cleaning and lubrication to storage and replacement parts. By following these tips, you can keep your tools in excellent condition and get the most out of them.

Whether you're a DIY hobbyist or a professional, these tips will help you maintain and extend the life of your rotary tools. So, let's get started and ensure your rotary tools stay in excellent condition for years to come.

Cleaning and Lubricating

Properly cleaning and lubricating your rotary tools after each use is essential to keeping them running smoothly and extending their lifespan. Here are some tips on how to clean and lubricate your rotary tools:

Cleaning

To clean your rotary tool after each use, first unplug it and disassemble any removable parts such as the chuck, collet, and bit. Use a soft brush or cloth to remove any debris or dust that has accumulated on the tool's exterior and interior. If there is stubborn dirt or debris, you can use a cleaning solution specifically designed for rotary tools.

Lubrication

After cleaning your rotary tool, it's important to lubricate the moving parts to prevent rust and corrosion and ensure smooth operation. The most commonly lubricated parts of a rotary tool include the bearings, motor shaft, and collet.

When choosing a lubricant for your tool, it's important to use one that is specifically designed for use with rotary tools. You should avoid using any lubricants that contain silicone, as they can damage the tool's plastic parts. Some popular lubricants for rotary tools include lithium grease, mineral oil, and synthetic lubricants.

When applying lubricant to your tool, it's important to follow the manufacturer's instructions and apply only a small amount. Too much lubricant can attract dust and debris, leading to clogging and other issues. After applying the lubricant, be sure to wipe away any excess with a clean cloth.

By properly cleaning and lubricating your rotary tools after each use, you can help ensure that they continue to function properly and last for years to come.

Storage

Proper storage is key to maintaining the longevity and functionality of your rotary tools. Here are some tips to help you properly store your tools:

Keep them dry

Moisture can cause rust and corrosion, so it's important to keep your tools dry. Make sure to dry them off after each use and avoid storing them in damp areas.

Use a case: A case can help protect your tools from dust and other debris that can accumulate and damage the moving parts. It also makes it easy to transport your tools to different job sites. You can purchase a case specifically designed for your rotary tool or use a general-purpose tool case.

Store them in a safe location

Rotary tools can be dangerous if not stored properly. Keep them out of reach of children and in a secure location where they won't be accidentally knocked over.

Keep them organized: Keeping your tools organized can save time and reduce frustration when you need to find a specific tool. Use a tool organizer to keep all of your rotary tool bits and rotary tool accessories in one place.

Avoid extreme temperatures

Extreme temperatures can affect the performance and lifespan of your tools. Avoid storing them in areas that are too hot or too cold.

When it comes to choosing the right storage solution for your needs, consider factors such as the size of your tool collection, how often you use your tools, and the environment where you will be storing them. Some popular storage solutions include tool chests, cabinets, and wall-mounted storage racks.

Common mistakes to avoid when storing rotary tools include leaving them out in the open where they can accumulate dust and debris, storing them in damp areas, and not keeping them organized. By following these tips and avoiding common mistakes, you can help ensure that your rotary tools are stored properly and ready to use when you need them.

Replacement

Even with regular maintenance and care, certain parts of a rotary tool will eventually need to be replaced. It's important to identify when parts need replacing in order to prevent further damage to the tool and ensure its continued performance. Here are some tips on how to identify when parts need replacing and how to find the right replacement parts for your tool:

Signs of Wear and Tear

Look for signs of wear and tear on the tool's components such as the chuck, collet, and motor brushes. If the chuck or collet is damaged, it may not hold the accessory securely or may wobble during use. If the motor brushes are worn down, they may not make proper contact with the armature and the tool may lose power or stop working altogether.

Reduced Performance: If the tool is not performing as well as it used to, it may be time to replace certain parts. For example, if the tool is vibrating more than usual or producing a strange noise, the bearings may need to be replaced.

Genuine Replacement

When looking for replacement parts, it's important to use genuine parts from the manufacturer. Using off-brand or generic parts can affect the tool's performance and can even damage the tool further.

Finding Replacement

Most manufacturers offer replacement parts for their rotary tools. Check the owner's manual or the manufacturer's website for a list of available parts. You can also try searching for the part number or description online. It's important to only purchase from a reputable seller to ensure that you receive a genuine replacement part.

DIY Repairs

Some rotary tool users may attempt to repair or replace parts themselves. While this can be a cost-effective solution, it's important to have the necessary knowledge and skills to avoid further damage or injury. If you're unsure about how to make a repair, it's best to seek the help of a professional.

By identifying when parts need replacing and using genuine replacement parts, you can extend the life of your rotary tool and ensure its continued performance.

Safety

Rotary tools can be incredibly useful in a variety of DIY projects, but it's important to prioritize safety when working with these powerful tools. In this section, we'll discuss some key safety considerations to keep in mind when using and maintaining rotary tools.

Wear Protective Gear

Before using a rotary tool, it's important to wear appropriate protective gear, such as safety goggles, ear protection, and a dust mask. These items can protect you from flying debris, loud noises, and harmful dust or fumes.

Follow Instructions

Always read the instructions that come with your rotary tool and follow them carefully. Pay attention to any safety warnings or precautions listed in the manual.

Check Your Workspace: Before beginning any project, ensure that your workspace is clean, well-lit, and free of clutter. Keep your rotary tool's cord and any extension cords out of the way to prevent tripping hazards.

Use the Right Accessories

Make sure to use the correct accessories and attachments for your rotary tool. Using the wrong accessory or attachment can be dangerous and could damage your tool.

Secure Your Workpiece

When working on a project, make sure to securely clamp or otherwise hold down your workpiece. This will prevent it from moving or shifting while you're using your rotary tool.

Use the Right Speed

Different projects require different speeds on your rotary tool. Be sure to adjust the speed settings to match the project you're working on. Running your tool too fast can be dangerous and can cause damage to your tool or your workpiece.

Take Breaks

Rotary tools can be very powerful and can cause fatigue and strain if used for extended periods of time. Take breaks every 20-30 minutes to stretch and rest your hands and arms.

Keep Your Tool Maintained

Regular maintenance is important for both the safety and longevity of your rotary tool. Follow the manufacturer's recommendations for cleaning and lubricating your tool, and be sure to replace any worn or damaged parts promptly.

Use Common Sense

Ultimately, safety comes down to using common sense. If something feels unsafe or risky, don't do it. Always prioritize your safety and the safety of those around you when using a rotary tool.

By following these safety tips, you can help prevent accidents and injuries when working with rotary tools. Remember to always prioritize safety and take the necessary precautions to protect yourself and those around you.

Tips For Choosing Rotary Tools

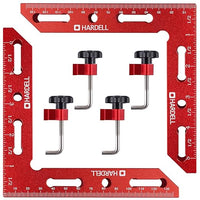

- Consider the brand reputation: Look for brands with a reputation for quality and durability, such as Hardell.

- Look for a variety of accessories: Choose a rotary tool that comes with a wide range of accessories, so you can tackle a variety of tasks.

- Choose the right size and power: Consider the size and power of the rotary tool, depending on the types of projects you plan to work on.

- Check for ergonomic design: Look for a rotary tool with a comfortable grip and easy-to-use controls to prevent hand fatigue and strain.

- Consider corded vs. cordless: Think about your preferences for mobility and flexibility, and choose between a corded or cordless rotary tool accordingly.

Overall, Hardell offers a range of high-quality rotary tools with a variety of features and accessories to suit different needs and preferences. Be sure to consider the brand when making your purchase decision.