Can You Cut Metal With a Rotary Tool?

Rotary tools are versatile handheld power tools that can be used for a wide range of applications, such as sanding, polishing, carving, drilling, and cutting. They are compact, lightweight, and easy to use, making them a popular choice for DIYers, hobbyists, and professionals alike.

Cutting metal is a common task for many DIYers and hobbyists, and it’s natural to wonder if a rotary tool can effectively cut metal. After all, rotary tools are not designed specifically for cutting metal, and their small size and low power may lead some to question their ability to handle such a task.

To understand whether or not rotary tools can effectively cut metal, it’s important to first understand how they work. Rotary tools typically have a high-speed motor that drives a spinning bit or cutting wheel. The bit or wheel is made of various materials, such as high-speed steel, tungsten carbide, or diamond, which can be selected based on the material being cut.

While rotary tools may not be the first tool that comes to mind when cutting metal, they can be effective when used properly.

In the following sections, we’ll explore some tips and techniques for cutting metal with a rotary tool, as well as some important safety considerations.

Types of metal that can be cut with rotary tools

Rotary tools are versatile and can be used to cut different types of metals. Some of the common metals that can be cut with rotary tools include aluminum, brass, copper, and steel. The properties of each type of metal determine their suitability for rotary tool cutting. For instance, aluminum is a soft metal that can be easily cut using rotary tools, while steel is a harder metal that requires a more powerful rotary tool to cut.

Cutting bits for rotary tool

Rotary tools are versatile and can be used for a variety of tasks, including cutting metal. However, the effectiveness of rotary tools in cutting metal heavily depends on the cutting bits used. The cutting bit is the component of the rotary tool that does the actual cutting, and selecting the right one for the job is crucial to achieving a clean, accurate cut.

There are several types of cutting bits available for rotary tools, each with its unique properties and benefits. The most common types include high-speed steel (HSS) bits, carbide bits, diamond bits, and abrasive bits.

HSS bit

HSS bits are made of a type of high-carbon steel and are known for their durability and ability to maintain their sharpness even when exposed to high temperatures. These bits are suitable for cutting softer metals such as aluminum and copper.

Carbide bit

Carbide bits are made of a composite material containing tungsten carbide and cobalt. They are stronger and more durable than HSS bits and are capable of cutting harder metals such as steel and iron. Carbide bits are also able to withstand higher temperatures than HSS bits, making them an ideal choice for longer cutting sessions.

Diamond bit

Diamond bits are the most expensive type of cutting bit but are also the most durable and versatile. They are capable of cutting through almost any material, including hard metals such as titanium and stainless steel.

Abrasive bit

Abrasive bits are coated with abrasive particles such as aluminum oxide or silicon carbide and are ideal for grinding and shaping metal. They are not designed for cutting through thick metal, but they are perfect for smoothing rough edges and shaping metal surfaces.

When selecting a cutting bit for a rotary tool, it is important to consider the type of metal being cut, the thickness of the metal, and the desired outcome. Using the wrong type of bit can result in damaged tools, ruined projects, and even personal injury.

Choosing the right cutting bit for your rotary tool is essential to achieving a clean, accurate cut when working with metal. Understanding the properties and benefits of each type of cutting bit and following safety guidelines can help ensure a successful and safe metal cutting project.

Cutting techniques for rotary tools

While rotary tools can cut through many types of metal, the technique used to cut metal with a rotary tool can vary depending on the type of metal being cut and the desired outcome. Here are some of the most common cutting techniques used with rotary tools:

Grinding

Grinding is the most common technique used for cutting metal with a rotary tool. Grinding involves removing metal from the surface of the material using an abrasive grinding bit. Grinding is effective for removing burrs, shaping metal, and removing rust or other surface imperfections.

Cutting

Cutting involves removing large sections of metal from a material to create a specific shape or size. Cutting with a rotary tool involves using a cutting wheel or disc that is designed specifically for cutting through metal. Cutting wheels come in various sizes and shapes, and can be used to make straight cuts or curved cuts.

Sanding

Sanding is a technique that involves removing the surface layer of metal from a material using sanding discs or drums. Sanding is useful for creating a smooth surface or removing rust or other surface imperfections.

Polishing

Polishing involves using a polishing bit or disc to create a smooth, shiny surface on a metal material. Polishing is often used to create a decorative finish on metal.

When using a rotary tool for metal cutting, it is important to use the appropriate bit or disc for the job. For example, a grinding bit is not effective for cutting through thick pieces of metal, while a cutting wheel may not be effective for removing rust or shaping metal.

It is also important to use the correct speed setting for the type of material being cut. High speed settings may be suitable for soft metals, while slower speeds may be more effective for harder metals.

Overall, cutting metal with a rotary tool requires some practice and skill. By choosing the appropriate cutting technique and using the correct bit or disc, hobbyists and DIYers can achieve precise cuts and create beautiful metalwork pieces.

Safety considerations when cutting metal with rotary tools

Metal cutting generates sparks and debris that can cause injury if they come into contact with the skin or eyes. It's essential to wear protective gear such as eye and ear protection, gloves, and dust masks to reduce the risk of injury. Additionally, it's important to have a safe workspace with adequate ventilation to prevent the inhalation of metal particles.

Tips for cutting metal with rotary tools

Cutting metal with rotary tools can be a tricky task, especially for beginners. Here are some tips to help you cut metal with your rotary tool:

Choose the right cutting bit

Hardell offers a range of cutting bits suitable for cutting different types of metals. Be sure to choose the appropriate bit for the metal you are cutting.

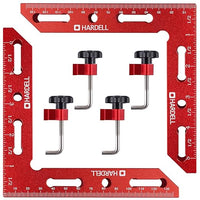

Secure the metal

When cutting metal, it is important to secure it properly to prevent it from moving or vibrating during the cutting process. You can use a clamp or vise to hold the metal in place.

Use lubrication: Adding a lubricant like cutting oil can help to keep the bit cool and reduce the risk of it getting damaged or worn out quickly. This is particularly important when cutting harder metals like steel.

Wear protective gear

Cutting metal with rotary tools can create a lot of dust and debris, which can be harmful to your eyes, ears, and respiratory system. Always wear eye protection, ear protection, gloves, and a dust mask when cutting metal.

Practice on scrap metal

If you are new to cutting metal with rotary tools, it is a good idea to practice on scrap metal first. This will help you get a feel for the tool and the cutting process before moving on to more valuable or delicate materials.

By following these tips, you can effectively cut metal with your rotary tool while also keeping yourself safe. Remember to always take your time, use the right tools, and wear the appropriate protective gear.

Conclusion

In conclusion, the answer to the question of whether or not you can cut metal with a rotary tool is a resounding yes. However, there are some important considerations to keep in mind.

First and foremost, it is essential to have the proper cutting wheel for the job. Using the wrong type of wheel can result in ineffective cutting or even damage to the rotary tool itself.

Additionally, it is important to wear appropriate safety gear when cutting metal with a rotary tool, such as safety glasses and gloves. Metal fragments can be dangerous and can cause serious injury if they come into contact with the eyes or skin.

When cutting metal with a rotary tool, it is also important to take your time and work slowly and carefully. Rushing the job or applying too much pressure can cause the cutting wheel to break or wear out too quickly.

Finally, it is important to properly maintain your rotary tool and rotary tool accessories to ensure their longevity and effectiveness. This includes regularly cleaning the tool and replacing worn or damaged parts as needed.

Overall, cutting metal with a rotary tool can be a highly effective and efficient way to get the job done. As long as you have the right tools, safety gear, and approach, you can confidently tackle a variety of metal-cutting projects with your rotary tool.